Within 5 days

10 am to 6 pm Monday to Saturday

B.tech Diploma( electrical or electronics), ITI & also working Professional..

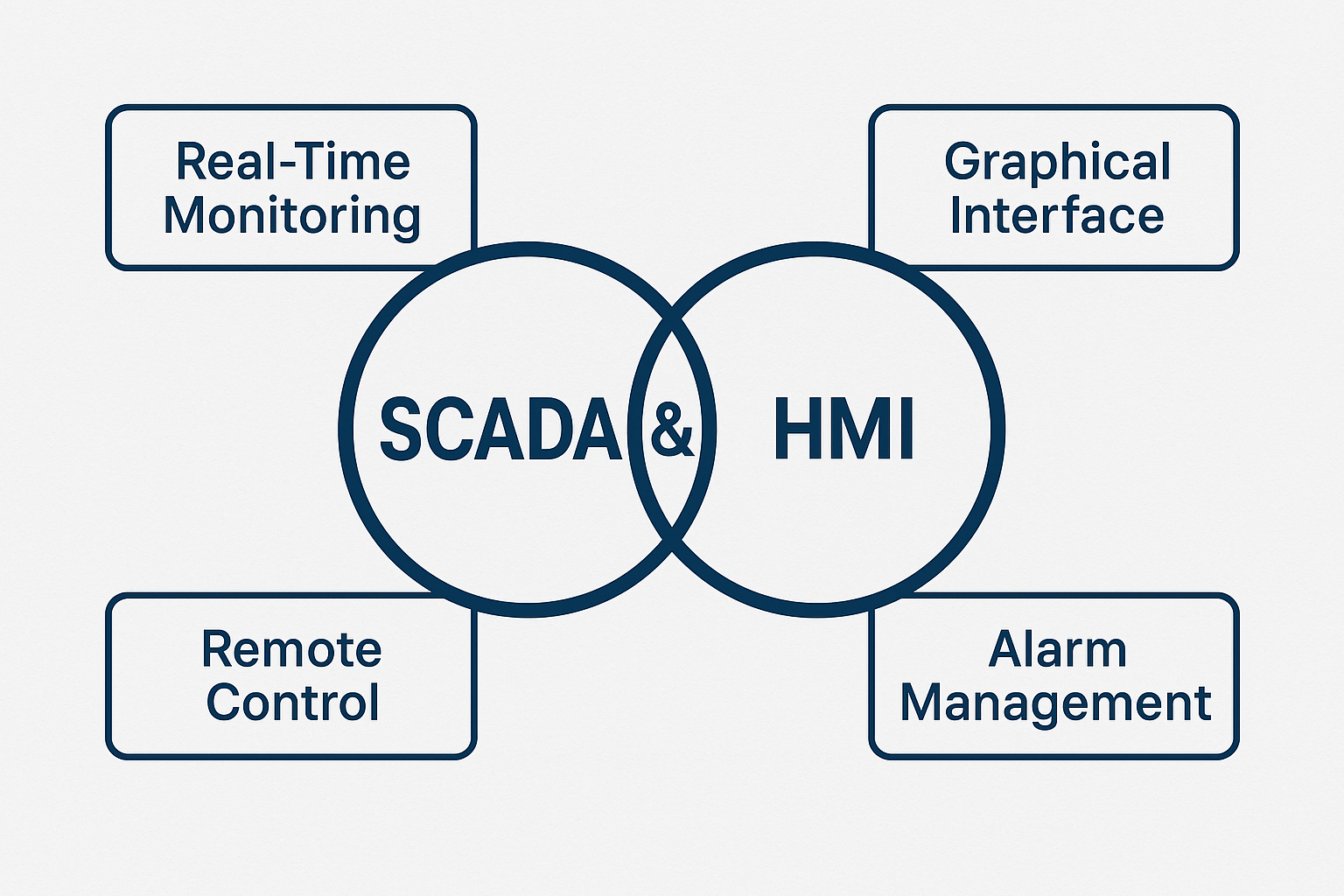

SCADA (Supervisory Control and Data Acquisition) & HMI (Human-Machine Interface) training covers monitoring and control of industrial processes. SCADA systems collect real-time data from PLCs, while HMI screens display this data to operators.

The training includes screen design, alarm configuration, historical data logging, and system integration.

SCADA (Supervisory Control and Data Acquisition) and HMI (Human-Machine Interface) are used to visualize, monitor, and control industrial processes.

At KP Automation, we are committed to shaping the future of industrial automation professionals.To providing comprehensive training in cutting-edge technologies like SCADA (Supervisory Control and Data Acquisition) and HMI .

SCADA (Supervisory Control and Data Acquisition) is a system used to monitor and control industrial processes remotely. It collects real-time data from field devices like PLCs and RTUs (Remote Terminal Units), processes it, and enables centralized control from a supervisory computer or control center

HMI (Human-Machine Interface) is the visual interface that operators use to interact with machines or automation systems. It typically displays process parameters, alarms, system status, and allows manual control inputs through touchscreens or computers.

KP Automation is a leading provider of industrial automation solutions, specializing in smart factory technologies and corporate training programs.

+91 74648 71880 / 63972 06850

info@kpautomation.co.in

Block-C, Village-Salimar, Landmark Near Indra Park, New Delhi – 110088, India

Get Directions on Google Maps© 2025 KP Automation. All rights reserved.